- Laboratories

- Hospitals

- Garages

- Manufacturing

- Pharmaceutical Plants

- Kennels

- Clean Rooms

- Schools

- Kitchens

- Commercial/Retail

- 1 gallon white pail - Resins

- 1 gallon black pail - Hardener

- Best suited for application in temperatures between 35°F and 85°F, with relative humidity less than 85%.

- When used as a primer, extra care is needed for substrate preparation and moisture content.

- Some light colors may require multiple coats for adequate hiding power.

- Certain colors may appear white when scratched.

- Slight batch-to-batch color variations may occur.

- Concrete must be structurally sound and free of curing membranes, paint, or other sealers.

- Concrete must be dry before application. Moisture testing is recommended with results below 3 lbs/1,000 s.f./24 hrs (ASTM F1869-11) or 75% internal relative humidity (F2170-11).

- Floor temperature and materials should be between 35°F and 85°F, with humidity below 85%. Do not coat unless the floor temperature is more than 5°F above the dew point.

- PPE per SDS

- Jiffy Mixer Blade (ES Model)

- Clean Mixing Container

- Low-Speed/High Torque Power Drill

- Shed-Resistant Roller Cover (3/8" Nap)

- Application Squeegee

- Mix ratio: 1 part Resin to 1 part Hardener by volume.

- Add 8-16 oz. of ProColor Universal Colorant per gallon if pigmenting.

- Add hardener into a clean mixing container first, then add resin and mix thoroughly for 1 minute using a Jiffler ES blade.

- Mix only enough material that can be applied within the pot life.

- Avoid scratching or gouging the surface.

- Do not drop heavy or pointed items on the floor.

- Rubber tires may stain the coating from plasticizer migration.

- Rubber burns from quick stops can permanently mark the surface.

Prospartic

ProSpartic is a low odor, high solids, aliphatic polyaspartic coating designed to be used as a clear or pigmented UV stable intermediate or grout/topcoat. Ideal for “Fast Track” projects and for use as a seal coat over decorative finishes. Reference technical data sheet for more information.

Typical Uses

Packaging

Storage

Materials should be stored indoors between 60°F (16°C) and 90°F (32°C).Shelf Life

One (1) year from date of manufacture.Limitations

Products Guide

| ProSpartic F-Resin | Accelerated cure for fast-track systems needing quick return to service or recoats. Applicable in low temperatures down to 35°F. Mix with ProSpartic Hardener at a 1:1 ratio for 6-20 mils thickness. |

| ProSpartic S-Resin | Longer working time, ideal for applications in higher temperatures and humidity. Mix with ProSpartic Hardener at a 1:1 ratio for 6-20 mils thickness. |

| ProSpartic Hardener | Compatible with both ProSpartic S and F-Resins at a 1:1 mix ratio. |

Preliminary Floor Inspections

Coverage Rate

| 20 mils | 80 sq ft/US gallon |

| 6 mils | 267 sq ft/US gallon |

Recoat Requirements

If recoating beyond 36 hours, lightly grind the existing topcoat with 100-grit diamonds, vacuum, and tack-wipe before reapplying.Mixing Instructions

Colors

See 'Color Guide'Cleaning Guidelines and Maintenance

Caution

Repairs

Repair gouges, scratches, or chip-outs promptly to prevent contamination.Disposal

Dispose in accordance with federal, state, and local regulations.Physical Characteristics

| Percentage Solid by Weight | 85% | |

| Mix Ratio | 1 Part Resin: 1 Part Hardener | |

| Viscosity | 800 cps (average) | |

| Cure Time | 2-3 hours (F-Resin); 8-10 hours (S-Resin) | 12 hours (F-Resin); 24 hours (S-Resin) |

| Working Time | 15 minutes | 25 minutes |

| Recoat Window | Maximum of 24 hours | |

| Service Temperature | Up to 230°F | |

| Coverage Rate | 80 sq ft/US gallon | 267 sq ft/US gallon |

| VOC | nil | |

| Abrasion Resistance | 15-20 mg loss | 10-15 mg loss |

| Coefficient of Friction | 0.7 (smooth) | 0.8 (smooth) |

Products

ProSPARTIC Hardener

Quick-setting cycloaliphatic polyaspartic hardener to be used with both ProSpartic S- and F-Resins. 1 part hardener to 1 part resin.

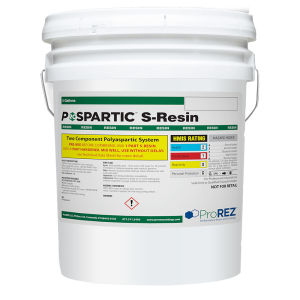

ProSPARTIC S-RESIN

High solids cycloaliphatic polyaspartic resin designed for applications with higher ambient temperature and humidity. Working time = 25 mins @ 70°F, 50% RH. Foot traffic = 6-8 hrs. 1 part resin to 1 part hardener.

ProSPARTIC F-RESIN

High solids cycloaliphatic polyaspartic resin designed for accelerated cure applications needing quick return to service or recoats. Working time = 15 mins @ 70°F, 50% RH. Foot traffic = 2-3 hrs. 1 part resin to 1 part hardener.

x1

x1

bundle Kit

bundle Kit includes