- Laboratories

- Hospitals

- Garages

- Laundries

- Pharmaceutical Plants

- Kennels

- Clean Rooms

- Schools

- Manufacturing

- Commercial/Retail

- 6 gallon white pail - Resin

- 5 gallon black pail - Hardener

- 1 gallon white pail - Resin

- 1 gallon black pail - Hardener

- 50 gallon drum

- Best suited for application in temperatures between 45°F and 90°F.

- Epoxy is light-sensitive to ambering over time and requires a UV stable topcoat.

- Some light colors may require multiple coats for adequate hiding power.

- Certain colors appear white when scratched.

- Slight batch-to-batch color variations may occur.

- When ordering to match a previous color, inquire if the same batch number or quality control number is still available.

ProPOXY

Typical Uses

Packaging

Storage

Materials should be stored indoors between 60°F (16°C) and 90°F (32°C).Shelf Life

One (1) year from date of manufacture.Limitations

Colors

See 'Color Guide'Physical Characteristics

| Percentage solids by weight | 100% |

| Mix Ratio (by volume) | 3 parts Resin & 1 part Hardener |

| Viscosity at 70°F | 500 cps |

| Pot Life at 70°F | LWT-Hardener: 30 mins S-Hardener: 20 mins F-Hardener: 10 mins |

| Cure Time, Tack-Free at 70°F | ProPoxy LWT-Hardener: 18 hrs foot traffic ProPoxy S-Hardener: 8-10 hrs foot traffic ProPoxy F-Hardener: 4-5 hrs foot traffic, 12-18 hrs for normal operation |

| Working Time at 70°F | 45 mins (LWT-Hardener) 25 mins (S-Hardener) 15 mins (F-Hardener) |

| Recoat Window | Maximum of 36 hrs |

| Coverage Rate | 10 mils, 160 sq ft/US gallon Can be applied to 6 mils, 267 sq ft/US gallon |

| Volatile Organic Compound (VOC) | nil |

Products

ProPOXY LWT Hardener

Long Working Time epoxy hardener for use with ProPoxy UVR, S-Resin or Cove Resin. Cures hard & ready to sand-screen in 14 hrs at 70°F. 3 parts resin to 1 part hardener.

ProPOXY S-HARDENER

Standard epoxy hardener for use with ProPoxy S-Resin or Cove Resin. Cures hard & ready to sand-screen in 10 hrs at 70°F. 3 parts resin to 1 part hardener.

ProPOXY F-Hardener

Faster setting epoxy hardener for use with ProPoxy S-Resin. Cures in 4-4.5 hrs @ 70°F. 3 parts resin to 1 part hardener.

ProPOXY S-Resin

100% Solids, all purpose epoxy resin for priming, mid, grout and top coats. Use with either ProPoxy S- or F-Hardener. 3 parts resin to 1 part hardener. Install at 6-20 mils.

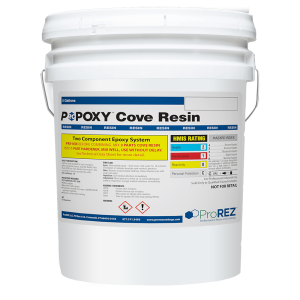

ProPOXY Cove Resin

Thickened epoxy for vertical surfaces and Cove Base. Use with either ProPoxy S- or F-Hardener. 3 parts resin to1 part hardener.

bundle Kit

bundle Kit includes